From Tailors to Tech: The Evolution of Measuring the Human Body

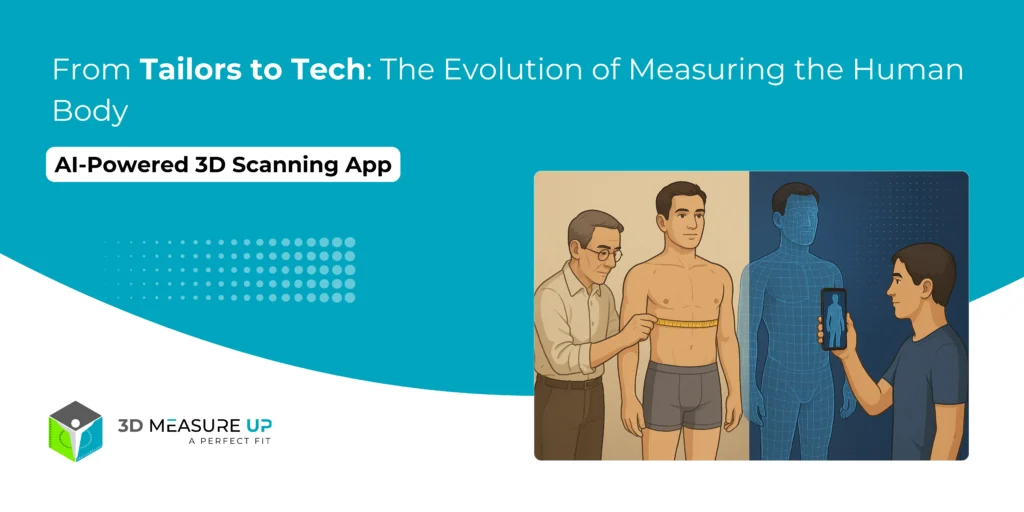

From Tailors to Tech: The Evolution of Measuring the Human Body For centuries, measuring the human body has been both an art and a science, driven by the need for well-fitted clothing, medical precision, and ergonomic designs. From the humble tape measure wielded by tailors to today’s AI-powered 3D scanning apps, the journey of body measurement techniques reflects humanity’s quest for accuracy, convenience, and personalization. This evolution has transformed industries like fashion, healthcare, and fitness, empowering individuals to obtain precise measurements at home. Platforms like 3D Measure Up by ProtoTech Solutions are at the forefront of this revolution, leveraging AI and 3D technology to redefine how we measure ourselves. The Age of Manual Measurement: Tailors and Tape Measures Body measurement began as a hands-on craft. In ancient times, tailors used rudimentary tools like knotted ropes or strips of cloth to capture body dimensions for custom garments. By the 19th century, the flexible tape measure, patented in 1829 by James Chesterman, became the gold standard. Tailors meticulously recorded measurements for chest, waist, hips, and inseams, relying on skill and experience to account for posture or body shape variations. While effective for bespoke clothing, manual measurement had limitations. Human error, inconsistent techniques, and the time-intensive process made it impractical for mass production. Variations of up to an inch were common, leading to ill-fitting garments. In medical settings, tools like calipers measured bone structure for diagnostics, but these, too, were prone to inaccuracies. The need for faster, more reliable methods grew as industries expanded. The Industrial Shift: Standardization and Anthropometry The 20th century brought industrialization and the rise of ready-to-wear clothing, demanding standardized sizing. Anthropometry, the scientific study of human body measurements, emerged to create size charts based on population data. Studies like the 1941 U.S. Army anthropometric survey measured thousands of soldiers to design uniforms, laying the groundwork for modern sizing systems. However, standardized sizes couldn’t account for individual variations, leading to fit issues in mass-produced clothing. In healthcare, anthropometric data improved prosthetic design and ergonomic products, but measurements still relied on manual tools like goniometers for joint angles or stadiometers for height. These methods, while more systematic, were labor-intensive and limited by the skill of the practitioner. The Digital Dawn: 2D Imaging and Early Automation The late 20th century introduced digital tools to body measurement. Early innovations included 2D imaging systems that analyzed photographs to estimate dimensions. Retailers experimented with body scanning booths in the 1990s, using laser or infrared technology to capture measurements for custom jeans or suits. These systems were faster than manual methods but expensive, bulky, and confined to specialized settings like malls or clinics. In medicine, digital calipers and motion capture systems improved precision for orthotics and posture analysis. Yet, these technologies were inaccessible to the average consumer, and their accuracy depended on controlled environments. The dream of at-home, user-friendly measurement tools remained out of reach until the rise of 3D scanning and AI. The 3D Revolution: Scanning and AI-Driven Precision The 21st century marked a turning point with 3D scanning technology. Unlike 2D imaging, 3D scanners capture a complete digital model of the body, mapping thousands of data points in seconds. Early 3D scanners, like those using structured light or laser triangulation, were used in high-end fashion and medical research. However, their cost and complexity limited widespread adoption. The game-changer came with the integration of AI and mobile technology. Smartphones, equipped with high-resolution cameras and depth-sensing capabilities (e.g., Apple’s ARKit or Google’s ARCore), democratized 3D scanning. AI algorithms now process these scans to identify landmarks, key points like the shoulder, waist, or knee, with precision rivaling professional tools. This shift has made accurate body measurement accessible to anyone with a smartphone. 3D Measure Up, developed by ProtoTech Solutions, exemplifies this leap forward. Using computational geometry and machine learning, 3D Measure Up extracts over 250 precise measurements from a single 3D scan. Its ability to handle diverse body shapes, poses, and even conditions like scoliosis ensures inclusivity. Whether for custom clothing, fitness tracking, or medical applications, the platform delivers repeatable, contactless measurements that outperform traditional tape measures. Its WebApp and API integration allow businesses to embed this technology into e-commerce platforms, reducing returns (which account for up to 40% of online apparel purchases due to poor fit) and enhancing customer satisfaction. Modern Applications: At-Home Measurement for Fashion and Health Today’s AI-driven tools empower users to measure themselves at home with unprecedented ease. For fashion, platforms like 3D Measure Up enable consumers to scan their bodies using a smartphone and receive tailored size recommendations for online shopping. This precision is a game-changer for e-commerce, where fit issues drive high return rates. Custom clothing brands can integrate 3D Measure Up’s API to offer made-to-measure garments without in-person visits, streamlining production and reducing waste. In fitness, 3D scanning tracks body changes with accuracy unattainable by manual methods. Gyms and wellness apps use tools like 3D Measure Up to monitor metrics like waist circumference or biceps size, visualizing progress to boost user motivation. The platform’s ability to export measurements to CSV files makes it ideal for integration with fitness trackers or coaching software. In healthcare, precision is paramount. 3D Measure Up supports medical applications like designing compression socks for diabetic patients or prosthetics for amputees. Its non-contact approach ensures hygiene and comfort, while its high accuracy (dependent on scan quality) aids diagnostics, such as posture analysis or obesity monitoring. By providing measurements aligned with global standards like ISO 8559, the platform bridges consumer and professional needs. The Future: AI and Beyond The evolution of body measurement is far from over. Advances in AI, augmented reality (AR), and wearable sensors promise even greater accuracy and accessibility. Imagine AR glasses guiding users to pose correctly for a scan or smart mirrors in stores generating instant 3D models. AI will continue to refine landmark detection, handling edge cases like loose clothing or complex body shapes. Platforms like 3D Measure Up are paving the way, with cloud-based APIs enabling seamless integration across industries. The