Validity, Accuracy, and Repeatability of Body Measurements extracted by 3D Measure Up

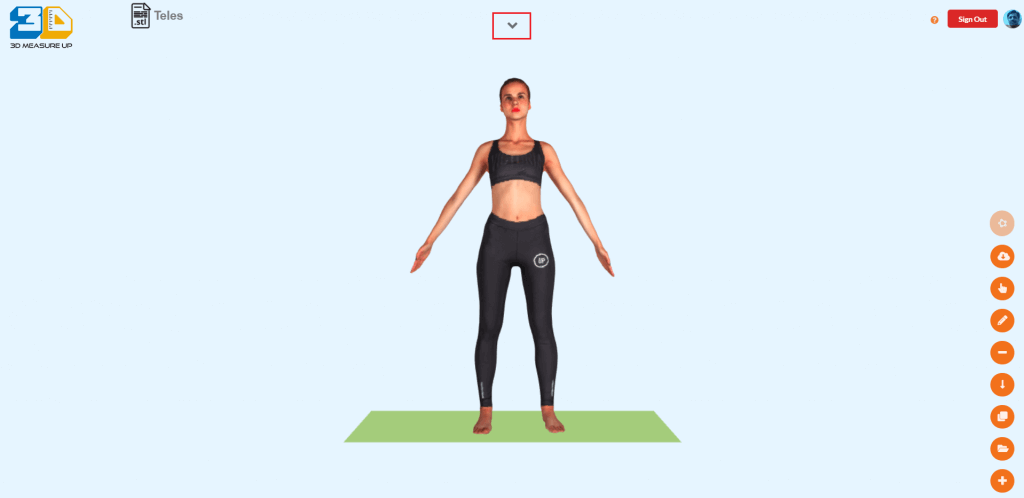

Human body measurement is a pillar in the apparel industry for the production of bespoke clothes with the most comfortable fit. Digital methods based on 3D scans are augmenting the traditional manual measurement techniques to improve the consistency, accuracy, and productivity of expert measurers. One of the concerns domain experts have is the quality of measurements obtained with 3D scanner-based measurements in terms of accuracy, reliability, and validity across different body shapes, postures, and poses.

A measurement extracted is automatically valid if it is the desired measurement as expected by the domain expert. In this case, the domain expert is the tailor master taking the measurements for the custom fitted suit. For determining the measurement accuracy it needs to be compared with a baseline. The baseline here is defined by the tape measurements taken by experienced masters. One of 3D Measure Up’s customers, an apparel manufacturer, wanted to know if our technology is reliable i.e. if we measured the same person repeatedly will we get the same results.

This study answers the question: How accurate and reliable is the 3D Measure Up Human body measurement platform? Or simply put: Is 3D Measure Up a dependable platform to be the core of a large bespoke apparel business?

Validity

What is a valid measurement?

For this study, to determine the validity of measurements we referred to ISO 8859-1 and ISO 20685 standard definitions and the method used by the expert measurers. We picked only those measurements whose definitions matched the expectations of the expert measurers.

Scanned 30 people, got their manual measurements, and compared the differences with automated measurements obtained from 3D Measure Up.

Sample population:

- Scanned subjects standing in a relaxed position

- with different body shapes, sizes, and postures

- wearing Formfit clothing

- Manually measured as soon as the scans were taken

Table 1.1 lists the measurements, definitions, and an illustration of the measurement as measured by the expert.

Measurement | 3D Measure UP ID | Definition | Reference Standard | ID as per Reference Standard | illustration |

Neck | 127 | Tape girth at the base of the neck measured in the plane passing through the back neck point and the front neck point | ISO 8859-1 | 1-5.3.3 |

|

Shoulder Width | 303 | Length along surface at the back of the neck, between the right shoulder point and left shoulder point | ISO 8859-1 | 1-5-4-2 |

|

Chest | 105 | Horizontal tape girth passing through the left and right front armpit points | ISO 8859-1 | 1-5.3.6 |

|

Under bust/Chest End | 106 | Horizontal tape girth passing directly below the bust line | ISO 8859-1 | 1-5.3.8 |

|

Bust | 144 | Horizontal tape girth measured at the bust point level | ISO 8859-1 | 1-5.3.4 |

|

Left Biceps | 125 | Girth of the left upper arm, mid way between the shoulder and elbow measured in the plane aligned to the axis connecting the center of the elbow and the shoulder point | ISO 8859-1 | 1.5l |

|

Right Biceps | 126 | Girth of the right upper arm, mid way between the shoulder and elbow measured in the plane aligned to the axis connecting the center of the elbow and the shoulder point | ISO 8859-1 | 1.5r |

|

Right Wrist | 121 | Tape girth at the right wrist point measured in the plane aligned to the axis connecting the center of the wrist and the elbow | ISO 8859-1 | 1-5.3.19r |

|

Left Wrist | 123 | Tape girth at the left wrist point measured in the plane aligned to the axis connecting the center of the wrist and the elbow | ISO 8859-1 | 1-5.3.19l |

|

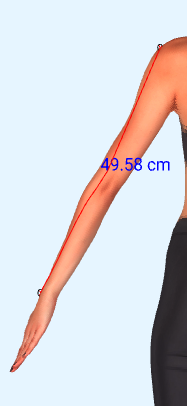

Left Upper Arm Length | 322 | Length along surface between the left shoulder point and left elbow point | ISO 8859-1 | 1-5-4-14l |

|

Left Lower Arm Length | 323 | Length along surface between the left elbow point and left wrist point | ISO 8859-1 | 1-5-4-15l |

|

Right Upper Arm Length | 321 | Length along surface between the right shoulder point and right elbow point | ISO 8859-1 | 1-5-4-14r |

|

Right Lower Arm Length | 324 | Length along surface between the right elbow point and right wrist point | ISO 8859-1 | 1-5-4-15r |

|

Right Outer Arm Length | 325 | Length along surface of the right arm, from shoulder point to wrist point through elbow point | ISO 8859-1 | 1-5-7-8r |

|

Left Outer Arm Length | 326 | Length along surface of the left arm, from shoulder point to wrist point through elbow point | ISO 8859-1 | 1-5-7-8l |

|

Front Chest Width | 329 | Length along surface (contoured) from between the front armpit poins | ISO 8859-1 | 3.3f |

|

Back Chest Width | 330 | Length along surface (contoured) from between the back armpit poins | ISO 8859-1 | 3.3b |

|

Waist | 108 | Horizontal tape girth of the torso measured at the waist level. Waist level for this girth is assumed at the 65% of the torso height. | ISO 8859-1 | 1-5.3.10 |

|

Back Chest Width | 330 | Length along surface (contoured) from between the back armpit poins | ISO 8859-1 | 3.3b |

|

Jacket Natural Waist | 145 | Girth is measured between the Underbust and Hip and passing through anterior-most point on the front of the avatar and the anterior-most point on the back of the avatar. | ISO 8859-1 | 1-5.3.10 |

|

Belly | 107 | Horizontal tape girth at the belly level | ISO 8859-1 | 1-5.3.11 |

|

Butt | 109 | Horizontal tape girth passing through the right and left hip points | ISO 8859-1 | 1-5.3.13 |

|

Left Side Neck to Waist Level Length | 315 | Length along surface on the front side of the avatar from the left side neck point to the point on the sagittal plane passing through the left neck point at the waist level | ISO 8859-1 | 1-5-4-11l |

|

Right Side Neck to Waist Level Length | 316 | Length along surface on the front side of the avatar from the right side neck point to the point on the sagittal plane passing through the right neck point at the waist level | ISO 8859-1 | 1-5-4-11r |

|

Right Side Neck Point To Belly Button | 331 | Length along surface on the front side of the avatar from the right side neck point to the point 2 inches ( 5.08 cm ) below the belly level on the mid sagittal plane |

|

|

|

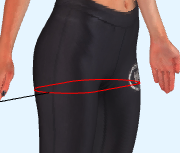

Crotch | 110 | Horizontal tape girth at the crotch level | ISO 8859-1 | 1-5.3.14 |

|

Left Thigh | 141 | Maximum horizontal tape girth of the left thigh below the gluteal fold. | ISO 8859-1 |

|

|

Right Thigh | 142 | Maximum horizontal tape girth of the right thigh below the gluteal fold. | ISO 8859-1 |

|

|

Right Mid Thigh | 112 | Horizontal tape girth of the right thigh measured midway between the crotch level and the Center of the point of the knee cap | ISO 8859-1 | 1-5.3.21r |

|

Left Mid Thigh | 111 | Horizontal tape girth of the left thigh measured midway between the crotch level and the Center of the point of the knee cap | ISO 8859-1 | 1-5.3.21l |

|

Right Knee | 113 | Horizontal tape girth of the right knee at the level of the Center point of the knee cap | ISO 8859-1 | 1-5.3.22r |

|

Left Knee | 114 | Horizontal tape girth of the left knee at the level of the Center point of the knee cap | ISO 8859-1 | 1-5.3.22r |

|

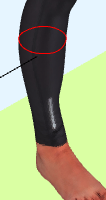

Left Calf | 136 | Maximum horizontal tape girth of the left calf, measured below the Center left Knee cap point and above the left Ankle point | ISO 8859-1 | 1-5.3.24l |

|

Right Calf | 137 | Maximum horizontal tape girth of the right calf measured below the Center right Knee cap point and above the right Ankle point | ISO 8859-1 | 1-5.3.24l |

|

Left Side Pant seam | 335 | Straight length from the crotch point to the ground along the inside of the right leg |

|

|

|

Right Side Mid Belly Hip To Ground | 333 | Free fall length measured from point midway between the hip level and belly level, to the Ground along the right side of the lower body |

|

|

|

Table 1.1

Result:

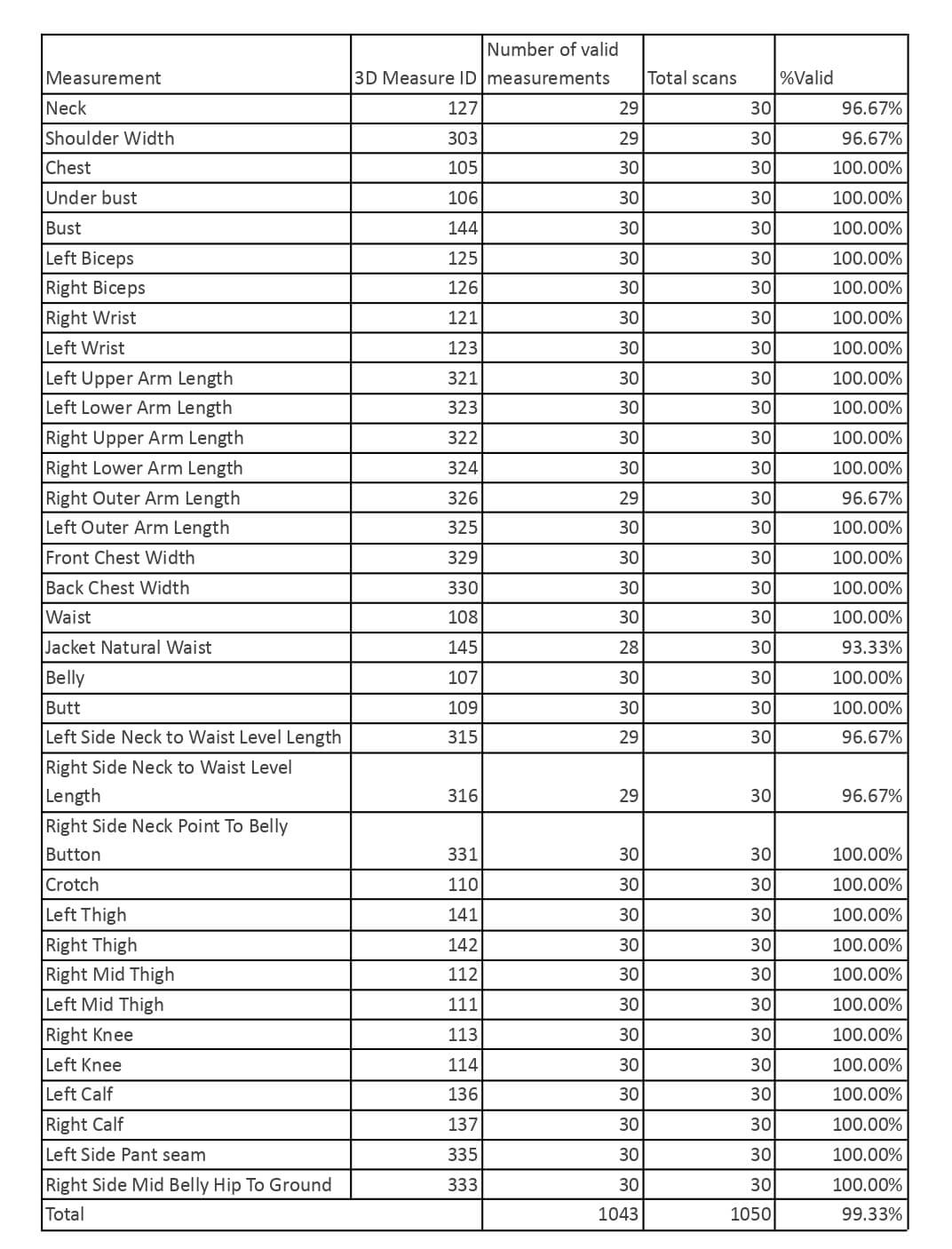

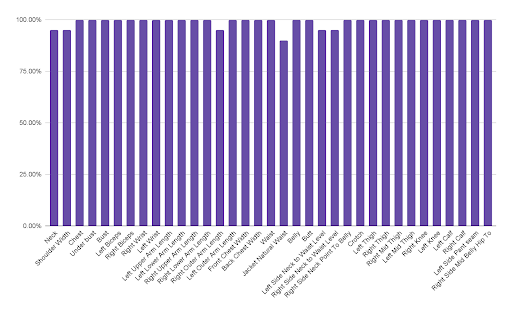

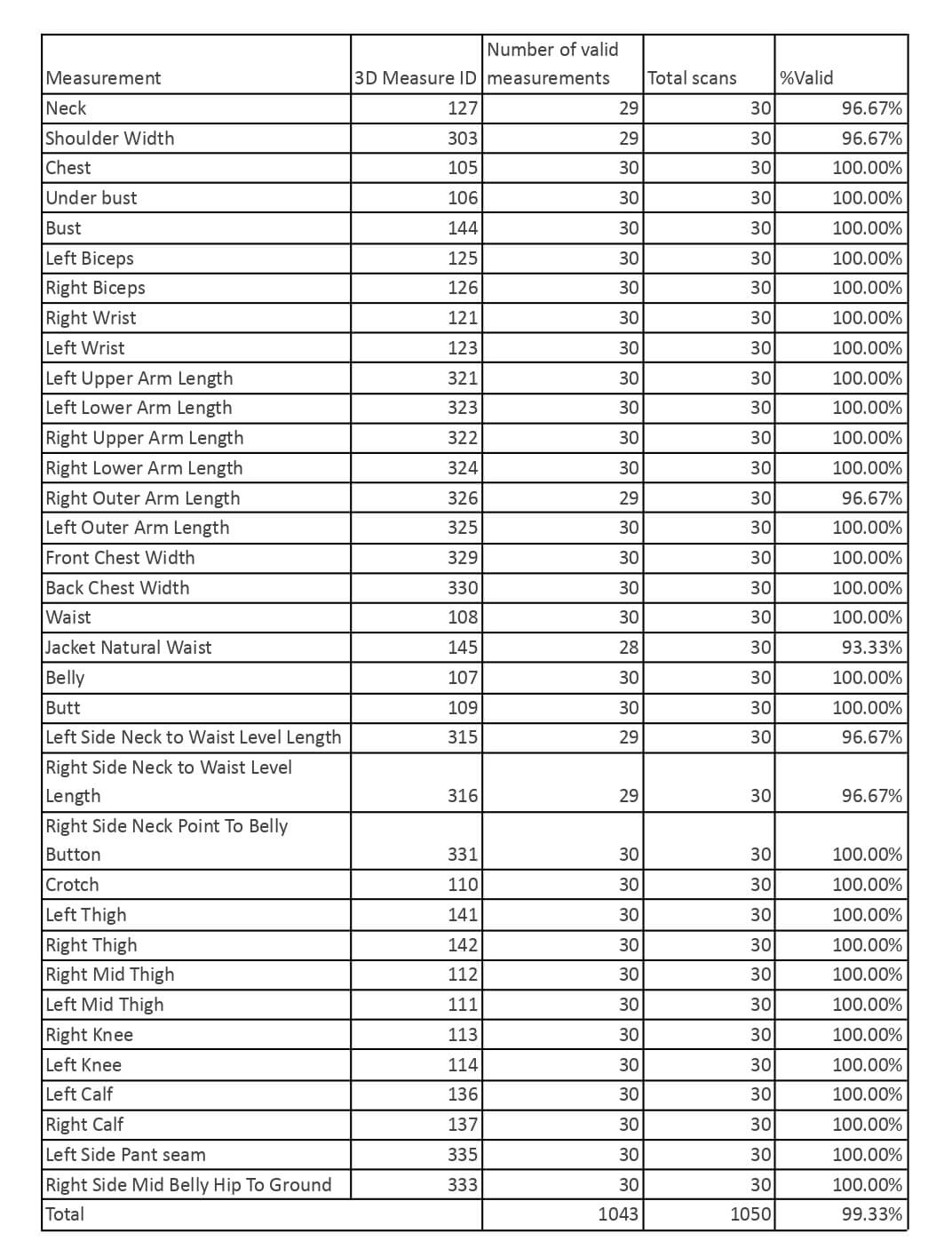

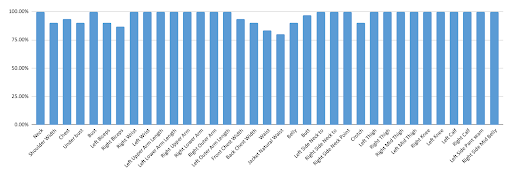

Table 1.2: Percentage valid measurements across 20 different persons

Table 1.2

Conclusion

3D Measure Up is able to extract valid measurements more than 99% of the time. Extreme obesity and body postural defects cause the measurements to be in the wrong place. In cases like the waist, a domain expert may have a different way of measuring, to make the custom-made wearable comfortable to the user. Though most 3D scanners today produce good scans there are cases where the scan may have defects like stray meshes and holes. The measurement extraction may be incorrect in such cases. It is recommended to clean and heal the mesh before measurements can be extracted.

Accuracy

What do we mean by Accuracy?

We have adopted the definition “Accuracy is compliance with definition and difference between manual and automatic measurements.” As customization is the need of the era, desired accuracy may be attained depending on the environment in which the scan is conducted and the specifications of the 3D scanner. This high level of precision ensures that measurements are precise the first time, requiring less effort to complete following design and production procedures.

How did we test?

Scanned 20 people, got their manual measurements, and compared the differences with automated measurements obtained from 3D Measure Up.

Sample population:

- Person is standing in a relaxed position

- Different body shapes, sizes, and postures

- Wearing Formfit clothing

- Measured as soon as the scans were taken

Tolerance or Acceptable Error Margin

The measurements by two different systems of measurement will never be exactly the same. To compare the measurements they should be within a tolerance or acceptable error margin. The acceptable error margin is different for each measurement depending on the position of the measurement on the body. It is also decided by the impact the measurement has on the comfort fit. For example, the Back Shoulder Width impact comfort most and hence has a lesser error margin. The error margin for the Chest is more as compared to the wrist measurement.

We referred to the ANSUR standard and also consulted with the domain experts to define the error margin for each measurement included in this study. Table 1.1 lists the acceptable error margins for bespoke apparel.

Results

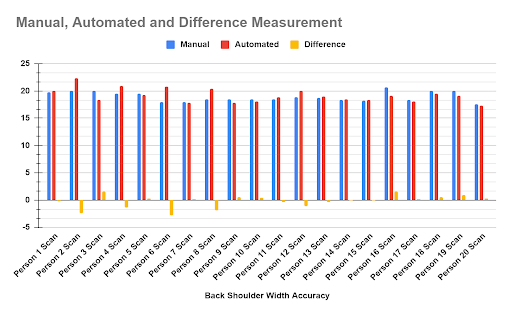

The following are the findings of 20 people who had their back shoulders measured both automatically(using 3D Measure Up Software) and manually. We have also captured measurements for different body parts. The purpose of this study was to examine the precision of 2 different tools for collecting anthropometric data on the shoulder.

The differential value was found to range from -0.09 to 1.6 inches.

Table 2.2: Percentage of accurate measurements across scans of 30 subjects

Cause of variations

- Accuracy of scans:

The discrepancy between the true measurement of what you’re scanning and the results of what you’ve scanned is what’s known as accuracy. The greater the discrepancy, the less accurate it is.

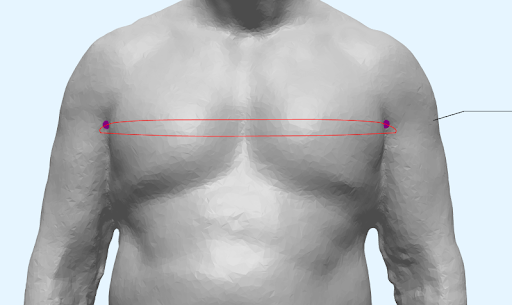

- Fused meshes:

When the subject is scanned in a relaxed posture. The arms get fused with the torso. The fused mesh areas cause problems in the identification of measurement points and body features.

Fig 1.0 Fused Chest Measurement

- Inherent manual measurement differences

It has been acknowledged that manual tape measurement of the circumference is normally smaller than surface measurement due to the tension of the tape

Conclusion

Since the accuracy of 3D Measure Up is tested in real-life scenarios rather than using test rigs or dummies and for most commonly used measurements, the results are dependable. Measurements were extracted manually by experts and by using 3D Measure Up match in more than 96% of the cases. The mismatch is mostly for trickly measurements like the waist. Each one has a little difference in the way the waist is measured and how tight the tape is while measuring.

Repeatability

What do we mean by Repeatability?

We tested 3D Measure Up for repeatability to know how reliable and dependable our system is.

Reliability is defined as the probability that a product will perform its intended function adequately for a specified period of time, or will operate in a defined environment without failure. We conducted reliability for 3D Measure Up software with the help of differences between automatic measurements derived from different scans of the same person. The scans are taken within a fixed period of time.

How did we test?

Scanned 4 people, 5 times within 15 minutes

Sample population:

- Person is standing in relaxed position

- Different body shapes, sizes, and postures

- Wearing Formfit clothing

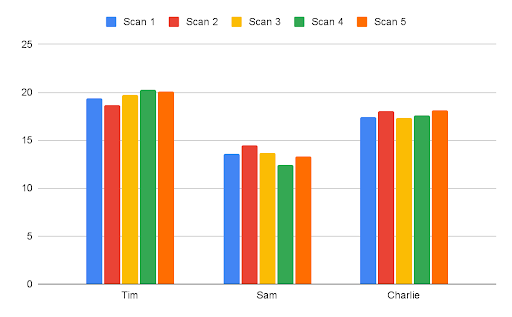

Results

The results of different scans of a person taken at 15-minute intervals are listed below. The scans appeared to have variations with the allowable tolerance.

The graph below shows the variations in the back shoulder width.

Cause of variations

1. The postures of individuals change slightly from one scan cycle to another. This slight change may result in the measurements being off.

2. Scan time matters as the body changes during the scan and between scans :

- Breathe-in and Breatheout volumes are different: Each scan should be taken in either a breathe-in or breathe-out state.

- Height can change during the whole day: The time difference between the scans should be minimal. (refer: https://jamaicahospital.org/newsletter/are-we-taller-in-the-morning/, https://www.bmbtrj.org/article.asp?issn=2588-9834;year=2017;volume=1;issue=2;spage=113;epage=119;aulast=Vuvor)

- Weight and volume changes based on the food and water intake i.e. is the stomach full or empty?

- Postural changes between two scans: Though the same person stands in the same pose the posture of the body is slightly different. eg. Hands in A pose may be slightly higher or lower. This adds to the variations in the biceps and chest regions.

- Alignment changes center: We have observed that the center of the body shifts slightly across scans.

- Weight distribution due to postural changes can affect the shape and volume of the muscles

- Tension in various muscles – pull knee muscles or contract glutes or chest muscles or fist open closed.

Observations

- The variations of the measurements across scans of the same person is within the tolerance limit.

- The repeatability of the measurements depends on the repeatability of the scanned object.

- The repeatability of the scanner depends on the duration between the scan intervals and changes in the body shape.

Conclusion

The information provided in the study will benefit the collection of anthropometric data for the whole body scan by bespoke apparel businesses. This study shows that the results provided by the 3D Measure Up are comparable to those collected using traditional methods and validate 3D Measure Up for use in anthropometric data collection for the whole body to manufacture bespoke wearables.

References :

https://3dbody.tech/cap/papers/2020/2041seifert.pdf

https://s3.amazonaws.com/io.structure.assets/White+Paper+-+Human+Limb+Scanning+with+Improved+Accuracy_v1.0+.pdf

https://3dbody.tech/cap/papers/2020/2035koval.pdf

https://www.researchgate.net/figure/The-standard-deviation-of-predicted-measurement-vs-ANSUR-allowable-error-in-milli-meter_tbl1_333624272

Contact us:

3dmeasureup@prototechsolutions.com

3D Measure Up