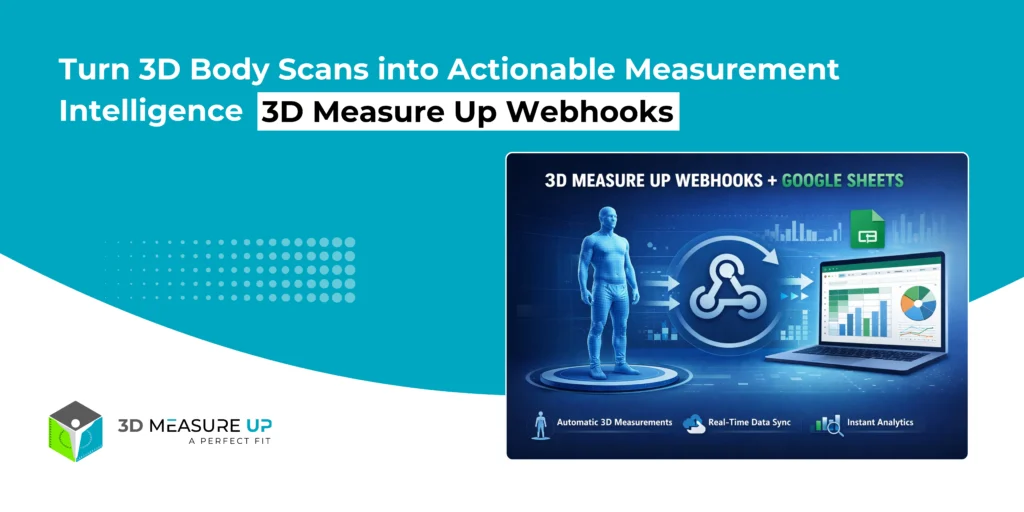

Turn 3D Body Scans into Actionable Measurement Intelligence — Instantly

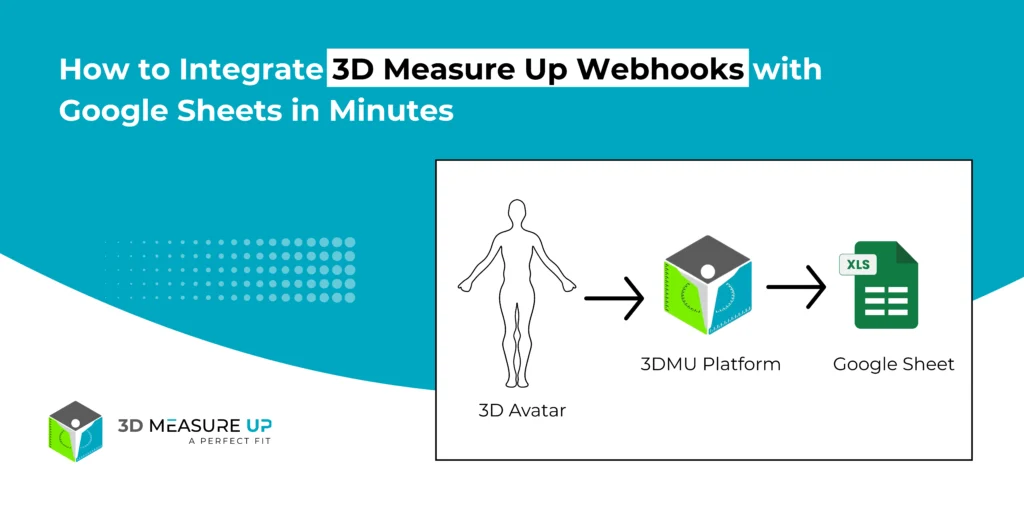

Turn 3D Body Scans into Actionable Measurement Intelligence — Instantly 3D Measure Up Webhooks: Real-World Business Workflows Using Google Sheets Capturing accurate 3D body measurements is only half the problem. The real challenge begins after the scan: How do teams access the data? How do non-technical users analyze it? How does it integrate into existing workflows without building custom software? 3D Measure Up Webhooks solve this problem instantly. With a simple webhook integration, 3D Measure Up can automatically push structured measurement data into Google Sheets, giving teams immediate visibility, analytics, and operational value without any backend development. Who Is This Integration For? This solution is designed for teams that want speed, simplicity, and insight—without infrastructure complexity. Apparel & fashion brands Retail operations teams QA & compliance teams Product & R&D analysts Healthcare & ergonomics professionals Startups and enterprises validating workflows If your team already uses Google Sheets for reporting, coordination, or analysis, this integration fits naturally into your workflow. What Business Problem Does This Solve? Most measurement systems fail after data capture. Common Challenges vs. Webhook Benefits Manual exports and CSV handling → Automatic data delivery Data trapped in proprietary systems → Open, accessible Sheets Inconsistent measurement formats → Normalized, analytics-ready structure Engineering dependency → No backend required Delayed insights → Real-time availability Result: Measurement data becomes usable the moment a scan is completed. What Happens When a Scan Completes? Each time 3D Measure Up generates measurements: A webhook event is triggered Measurement data is securely sent to your Google Apps Script endpoint Google Sheets automatically appends the data Teams can analyze, filter, and share instantly No polling. No downloads. No custom servers. Why Google Sheets? Google Sheets is more than a spreadsheet; it’s a collaboration and analytics layer. With 3D Measure Up Webhooks, Sheets becomes: A live measurement log A QA dashboard A reporting and audit tool A bridge to BI tools and ERP systems Designed for Scale: Clean, Analytics-Ready Data Instead of generating hundreds of columns per scan, 3D Measure Up follows an industry-standard tidy data approach: One row = one measurement This enables: Unlimited measurement expansion Easy pivot tables and charts Seamless BI exports Long-term maintainability This design choice is critical for real-world, scalable deployments. From 3D Scan to Measurement Intelligence End-User Applications Apparel & Fashion Centralized measurement repositories Pattern-maker-friendly exports Size consistency validation Reduced rework and returns Retail & Store Operations Store-wise measurement tracking Operator quality checks Scan volume and performance analytics Product & R&D Teams Population-level measurement analysis Sizing system validation Model and pose comparison Faster prototyping feedback loops Healthcare & Ergonomics Structured anthropometric datasets Longitudinal (before/after) tracking Easy clinician and researcher access QA, Audit & Compliance Timestamped measurement records Traceability to scan and model Exportable audit trails Reduced reliance on manual logs Why This Matters for Decision Makers This integration delivers measurable ROI: Faster insights (minutes, not weeks) Zero engineering dependency Immediate analytics Auditable and traceable data Faster rollout across teams It transforms 3D scanning from a technical capability into a business-ready system. Security & Control Built In Webhook endpoints are isolated and secure No direct access to Google Sheets is required URLs can be rotated at any time No exposure of internal systems This makes the solution suitable for both enterprise pilots and production workflows. When Should You Use a Backend Instead? Google Sheets is ideal for: Reporting Quality Assurance (QA) Analytics Prototyping Collaboration For very high data volumes, regulated environments, or long-term system-of-record storage, 3D Measure Up Webhooks can also integrate with custom backends, data lakes, BI pipelines, and ERP systems, using the same webhook mechanism. Read related: How to Integrate 3D Measure Up Webhooks with Google Sheets in Minutes Final Thoughts - The Bigger Picture 3D Measure Up Webhooks are not just an integration feature; they are an enablement layer. They allow organizations to: Start simple Prove value quickly Scale responsibly Integrate deeply when ready With 3D Measure Up Webhooks: Measurements flow automatically No backend development is required Data remains clean and scalable Teams gain immediate visibility Business value starts from day one Webhooks deliver the data. Google Sheets makes it usable. 3D Measure Up makes it valuable. If you have any questions, please contact us at 3dmeasureup@prototechsolutions.com