Perfect | Accurate Automatic body Measurements

Requirements for Accurate measurements

3D Measure Up makes the best effort to identify landmarks from scans of people in different poses and scans of varying quality. Having said that, for accurate and reliable measurements required for MTM or bespoke applications, we recommend the following:

1. Mesh Quality:

A good quality mesh received from the scanner will yield better results.

The expected mesh has the following qualities:

a) It is a single, triangular mesh.

b) It has watertight mesh i.e. no holes.

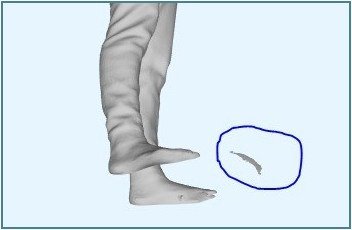

c) It has no stray triangles or disjoint meshes.

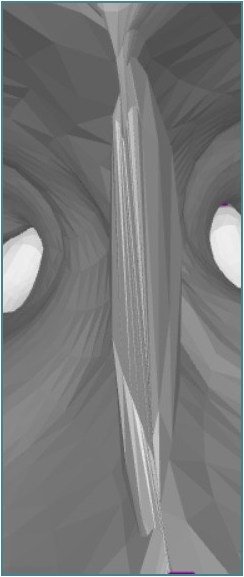

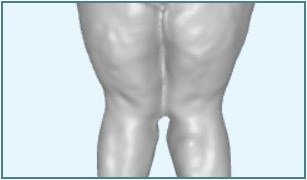

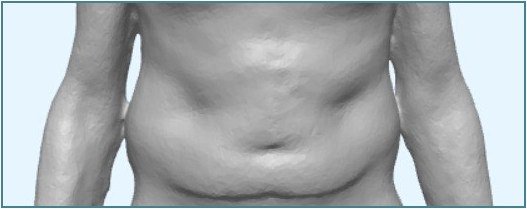

d) It has no broken mesh or self-intersecting meshes. These occur usually on parts of the body with folds. Eg. armpits, crotch, elbows, back of the knee, the web between the fingers.

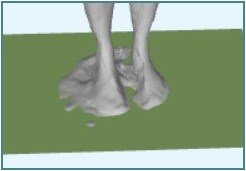

e) It has no platform below the feet, attached to the scan.

f) Avoid fused body parts.

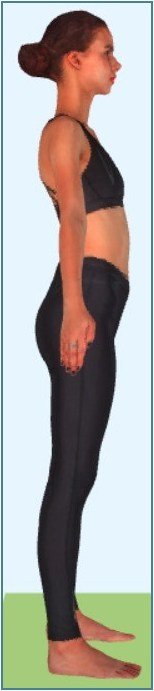

2. Pose:

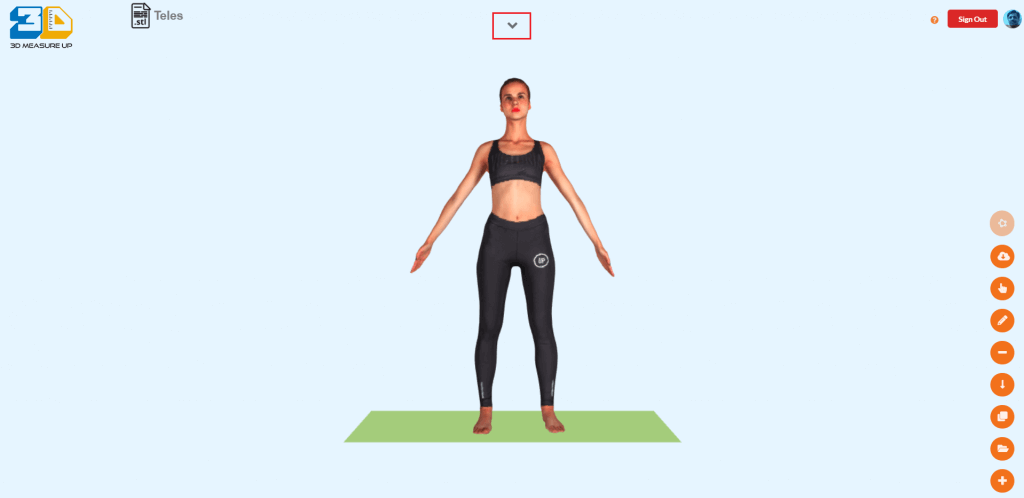

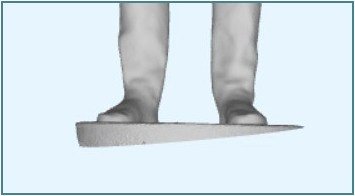

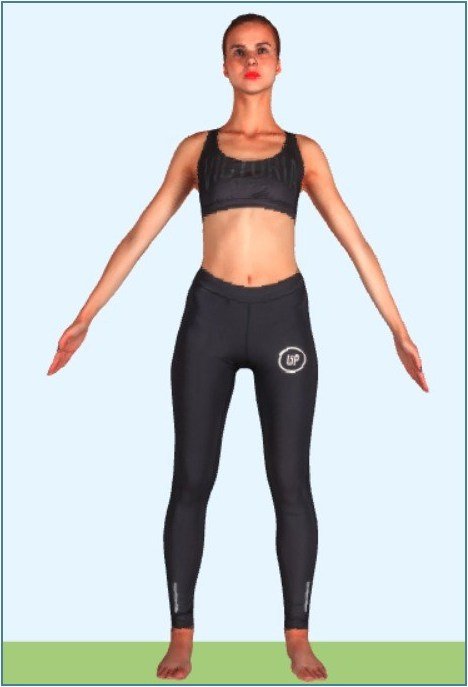

Though 3D Measure Up can handle any pose, the ‘A’ pose is ideal – the model standing with arms straight and pointing downwards.

Fig: Model standing with arms straight and pointing downwards.

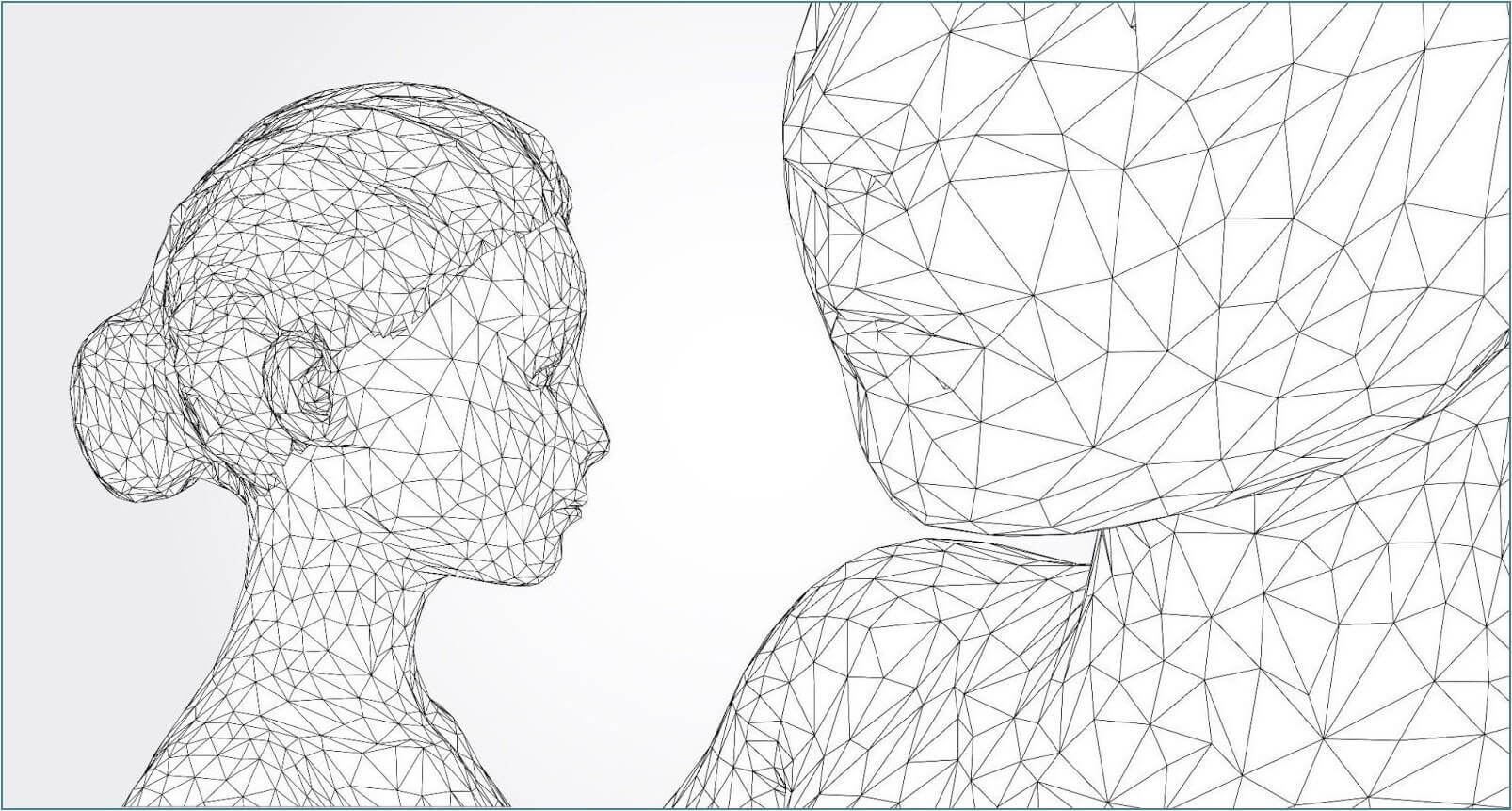

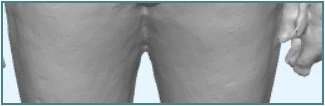

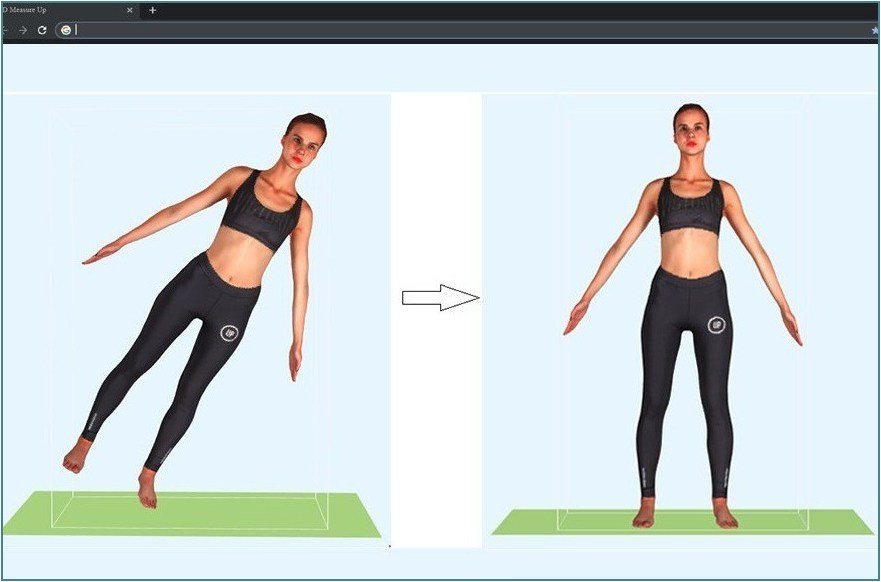

3. Alignment:

A perfectly aligned model (no leans, no stoops) with ‘+Y’ along the height of the person is ideal. Having said that, 3D Measure Up has inbuilt capability to correct alignment.

Fig: Perfectly aligned model.

4. Mesh Size:

Having said that, it is our observation that mesh size between 7MB to 12MB yields enough precision for most of the general applications.

Beyond 12MB, the impact on performance may not be worth the increase in precision. Though you may want to validate this specifically for your requirements.

Fig: Mesh size between 7MB to 12MB.

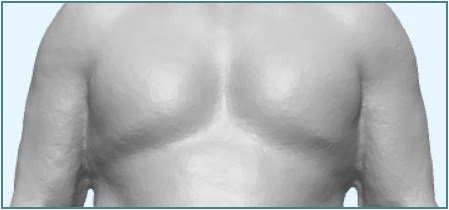

5. Clothing, hair styling, and other accessories:

The clothes should be tight-fitting to get accurate measurements. Accessories straying out of the body surface or altering profile are best avoided. Hair should ideally be tied and tucked neatly as close as possible to the head.

Fig: Model for clothing, hair styling & other accessories.

Contact us:

3dmeasureup@prototechsolutions.com

3D Measure Up