Use Case: Custom Fitted Compression Socks For Diabetic Patients

It is estimated that approximately 10% of the population over 18 years is affected by diabetes. About 1.4 million new cases of diabetes are diagnosed in the United States every year. And it is well known that people with diabetes must take very good care of their lower bodies esp. The feet area. They tend to suffer from various foot conditions and any injury can take a long time to heal. Diabetic socks are designed to help these patients from developing injuries. Diabetic socks also offer maximum blood flow and keep the feet dry. Along with keeping the foot healthy, they also offer comfort.

So, what is so special about diabetic socks? A lot of thought and design goes into making these. Diabetic socks should be loose, non-constricting, & have a super stretch. Tight socks can inhibit circulation, which might be challenging for those who suffer from circulatory issues. This means these socks have to fit perfectly and preferably tailor-made to an individual’s size.

The available evidence suggests that people with diabetes who have “normal” feet should be able to wear whatever socks they find to be comfortable. Socks should fit well, without constricting cuffs, lumps, or uncomfortable seams. Therefore, fitted socks are preferable to tube socks.

Indeed, the application of compression stockings would seem to be fairly cut and dry, Take leg measurements, use the manufacturer’s guidelines for determining the level of compression, choose a style, and hand over to the patient.

But that is not the case. For some are patients simple stockings with light pressure are good enough to prevent or reduce mild swelling. For patients with significant edema or venous leg ulcers or peripheral arterial disease (PAD) or peripheral vascular disease (PVD) prescription compression hosiery is necessary. Prescribing compression hosiery needs proper diagnosis and accurate measurements.

Measurements required for making custom compression stockings

- Girth of the ankle around the narrowest part, above the ankle bone.

- Distance of the calf from the back of the heel to the bend in the knee.

- Girth of the widest part of the thigh just below the gluteal fold.

- Distance of the thigh from the gluteal fold to the back of the heel.

- Girth of the widest part of the calf.

- Girth of the widest part of the hips.

- Girth of the waist.

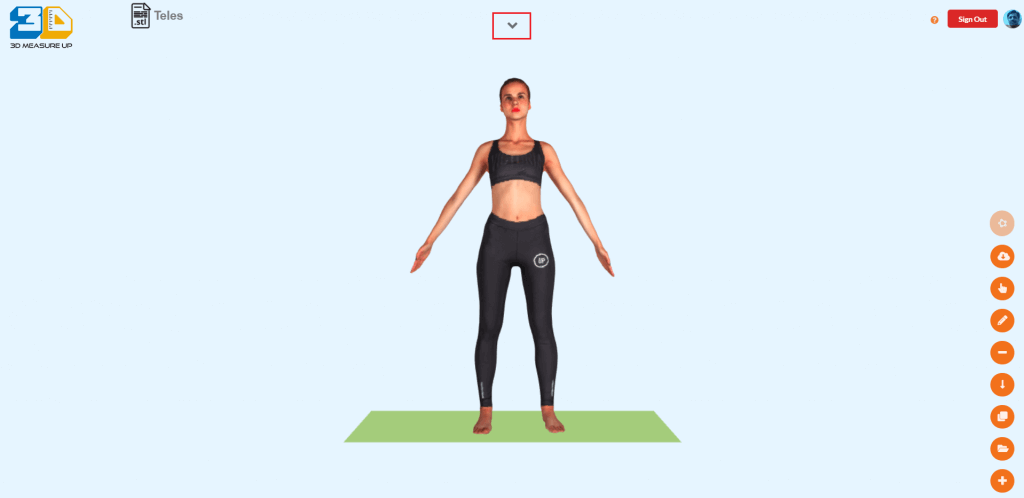

A few years back, getting such measurements would require a very personalized service involving a cumbersome and costly process. Today, we have technology where this can be achieved better, faster, and cheaper. 3D Measure Up enables a person to get the above measurements from a 3D scan of the leg accurately and precisely. Here are some of the major advantages of using technology viz. 3D Measure Up to design compression socks.

- Details: Get detailed measurements. With 3D Measure Up, you can measure far more landmark points on the foot than manual methods

- Accuracy: 3D Measure Up is highly accurate. It overcomes all the limitations and errors that are associated with manual measurements.

- Fast: Using 3D Measure Up drastically reduces the time required. It avoids needing visits to the clinic and is highly accessible.

- Simple: For manual measurements, you need an expert anthropometrist. 3D Measure Up can be used by anyone with very little training.

The links below describe how to extract measurements and perform operations on the model with 3D Measure Up.

- How to extract measurements from scans of a legs

- How to load a model in 3D Measure Up Web Application

- How to align a model in 3D Measure Up Web Application

- How to automatically extract measurements from a 3D model

- How to use the measurement tree to show, hide, and export landmarks and measurements in 3D Measure Up Web Application

To know more about the Measurement of Custom made socks and Compression socks for diabetics Measurement, please visit www.3dmeasureup.com. Click here to signup for a free trial of A Made-to-measure socks, or contact us at 3dmeasureup@prototechsolutions.com

Author: Pankaj C.

Contact us:

3dmeasureup@prototechsolutions.com

3D Measure Up